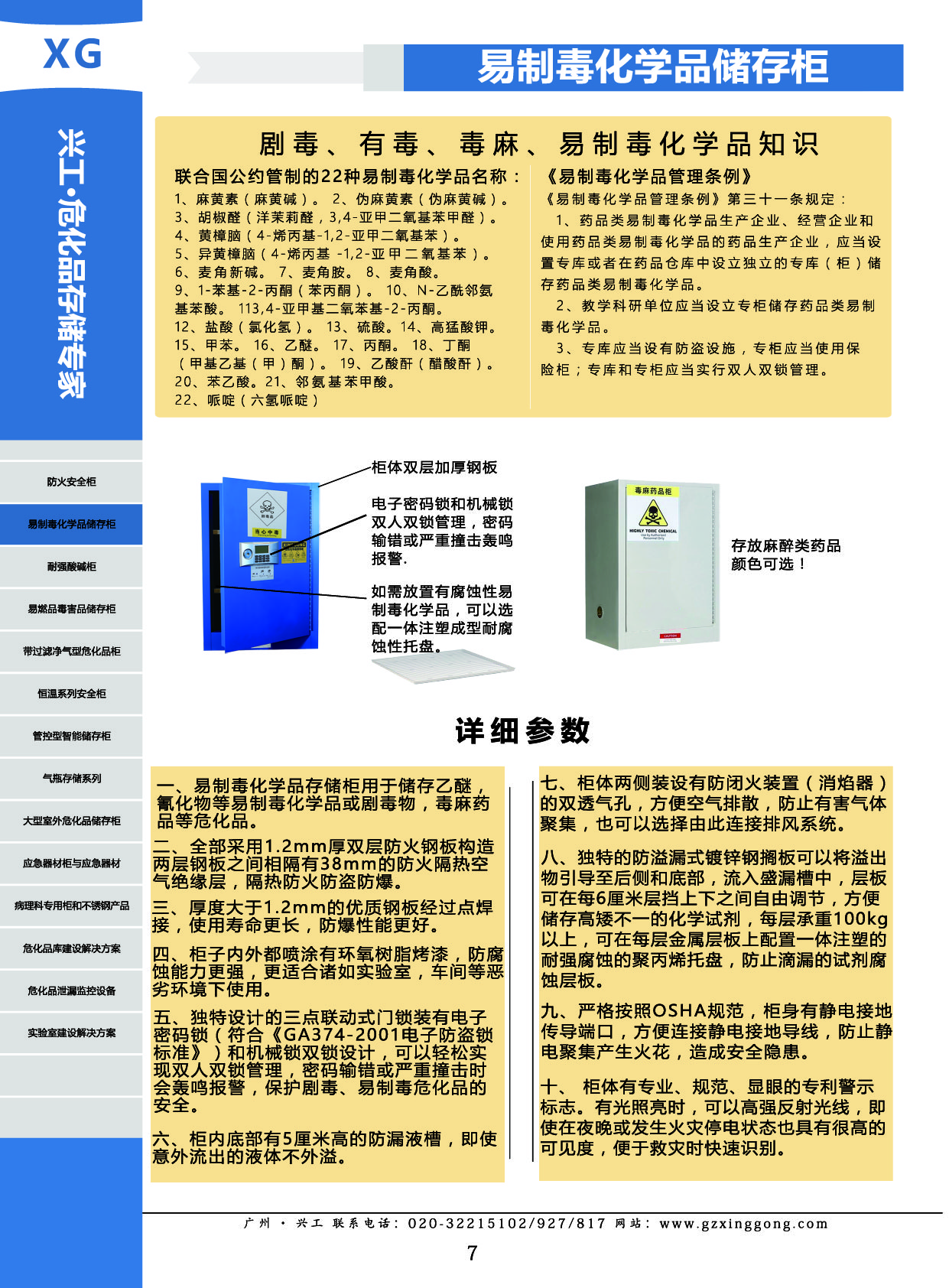

型号 | 外型尺寸 | 容量 | 层板数 | 门类型 | 颜色 |

XGD4F | 430*430*560 | 4/15 | 1 | 单门 | 蓝/灰 |

XGD12F | 590*460*890 | 12/45 | 1 | 单门 | 蓝/灰 |

XGD22F-2 | 600*460*1650 | 22/83 | 2 | 单门 | 蓝/灰 |

XGD22F | 890*560*890 | 22/83 | 1 | 双门 | 蓝/灰 |

XGD300F | 1090*460*1120 | 30/114 | 1 | 双门 | 蓝/灰 |

XGD450F | 1090*460*1650 | 45/170 | 2 | 双门 | 蓝/灰 |

XGD600F | 860*860*1650 | 60/227 | 2 | 双门 | 蓝/灰 |

XGD900F | 1090*860*1650 | 90/341 | 2 | 双门 | 蓝/灰 |

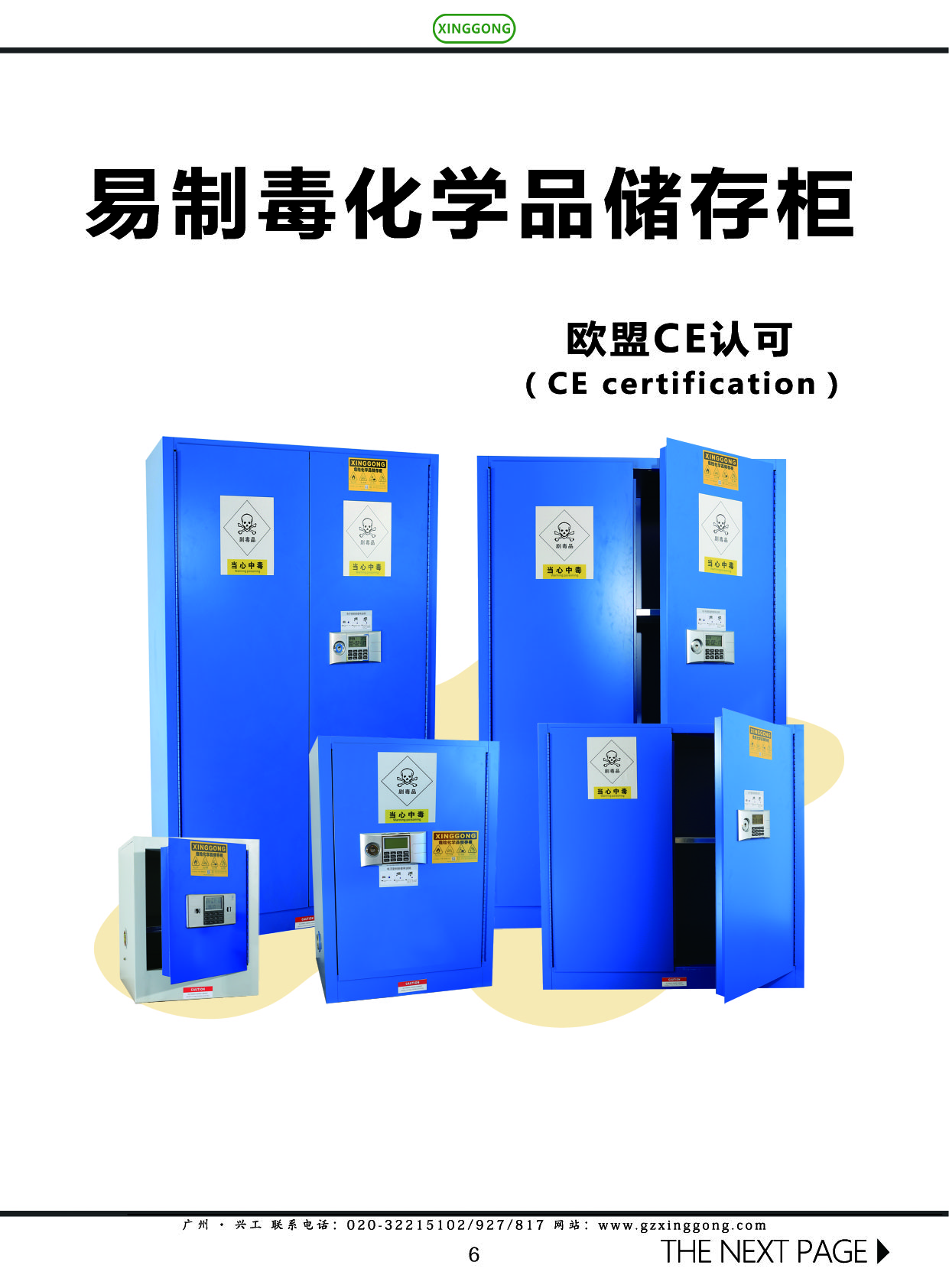

Parameters of the storage cabinet for precursor chemicals:

1. The product has passed the EU CE certification;

2. Adopting a 1.2mm thick double-layer fireproof steel plate structure, the high-quality 1.2mm steel plate is spot welded for a longer service life and better explosion-proof performance; There is a 38mm fire-resistant and heat-insulating air insulation layer between the two layers of steel plates, which is fire-resistant, heat-insulating, anti-theft, and explosion-proof;

3. The uniquely designed three-point linkage door lock is equipped with an electronic password lock (* the lock must comply with the GA374-2001 Electronic Anti Theft Lock Standard) and a mechanical lock dual lock design, which can easily achieve dual person dual lock management of hazardous chemicals. When the password is entered incorrectly or severely impacted, an alarm will sound, protecting your highly toxic and easy to produce hazardous chemicals;

4. There is a 5cm high leak proof liquid tank at the bottom of the cabinet to prevent accidental liquid leakage from overflowing;

5. Both sides of the cabinet are equipped with anti fire devices and double ventilation holes with flame suppressors, which facilitate air dispersion and prevent the accumulation of harmful gases. It can also be connected to the exhaust system through this connection;

6. The unique spill proof galvanized steel shelf can guide spilled materials to the back and bottom, flowing into the leak containment tank. The layers can be freely adjusted between the upper and lower layers every 6 centimeters, making it convenient to store chemical reagents of different heights and sizes. Each layer can bear a weight of more than 100kg* Each layer of metal laminate is equipped with an integrated injection molded polypropylene tray that is resistant to strong acid and alkali corrosion, to prevent dripping reagents from corroding the laminate;

7. The inside and outside of the cabinet are sprayed with epoxy resin paint, which has stronger corrosion resistance and is more suitable for use in harsh environments such as laboratories and workshops;

8. Strictly follow the OSHA regulations, and the cabinet body is equipped with static grounding conductive ports to facilitate the connection of static grounding wires and prevent the risk of sparks caused by static electricity accumulation;

*9. The cabinet is equipped with professional, standardized, and eye-catching patent warning signs. When illuminated by a flashlight, it can reflect light with high intensity and provide clear warnings even at night or in case of fire or power outage, making it easy to quickly identify during disaster relief;

客服1

客服1