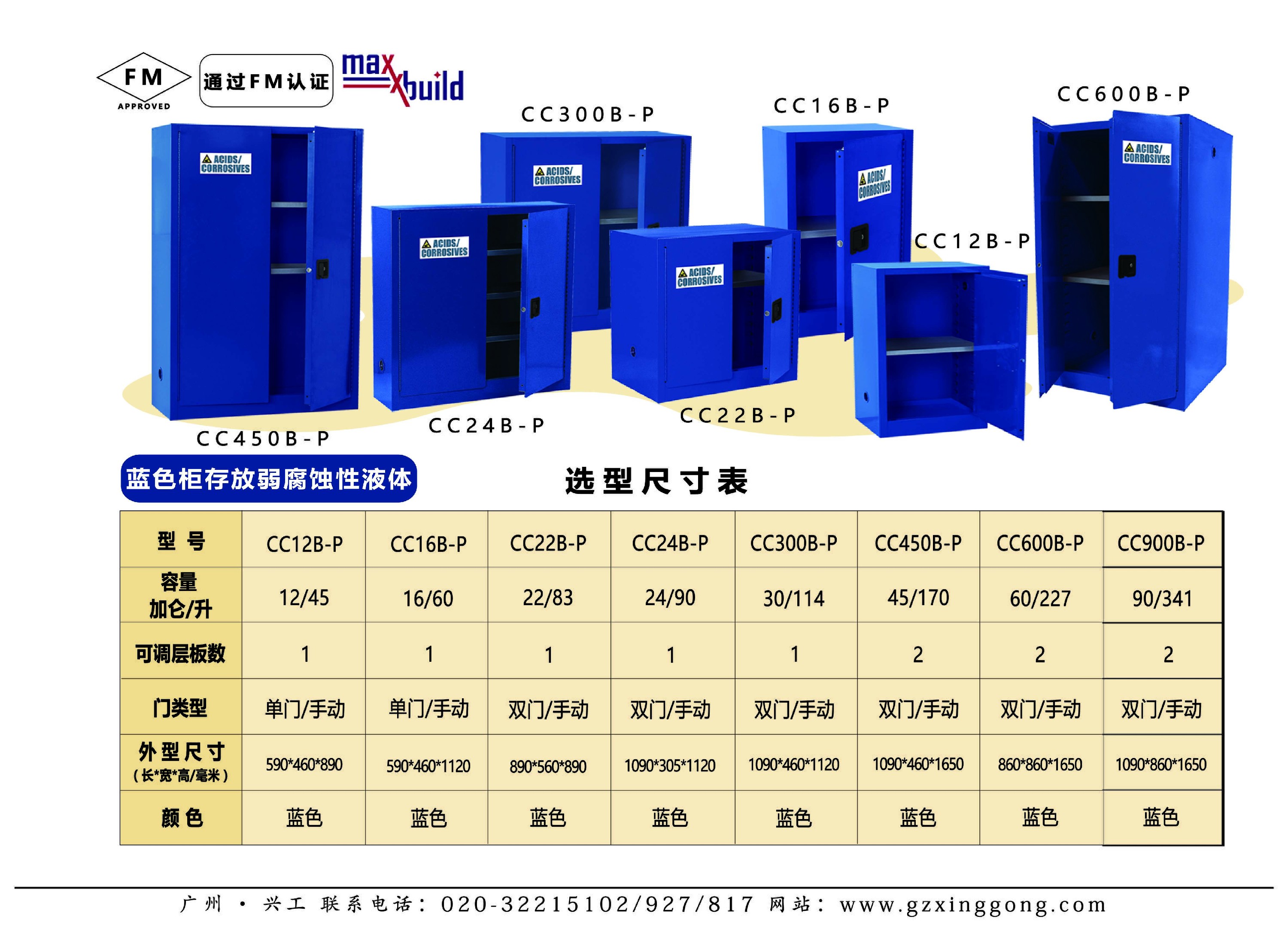

弱腐蚀液体安全柜:防火安全柜/防爆柜,美国FM消防防火认证产品 规格尺寸表 | |||||

型号 | 外型尺寸 | 容量 | 层板数 | 门类型 | 颜色 |

CC004 | 430*430*560 | 4/15 | 1 | 单门/手动 | 蓝色 |

CC12B-P | 590*460*890 | 12/45 | 1 | 单门/手动 | 蓝色 |

CC16B-P | 590*460*1120 | 16/60 | 1 | 单门/手动 | 蓝色 |

CCV22B-P | 590*460*1650 | 22/83 | 2 | 单门/自动 | 蓝色 |

CC22B-P | 890*560*890 | 22/83 | 1 | 单门/手动 | 蓝色 |

CC24B-P | 1090*305*1120 | 24/90 | 3 | 单门/手动 | 蓝色 |

CC300B-P | 1090*460*1120 | 30/114 | 1 | 双门/手动 | 蓝色 |

CC450B-P | 1090*460*1650 | 45/170 | 2 | 双门/手动 | 蓝色 |

CC600B-P | 860*860*1650 | 60/227 | 2 | 双门/手动 | 蓝色 |

CC090 | 1090*860*1650 | 90/341 | 2 | 双门/手动 | 蓝色 |

CC110 | 1500*860*1650 | 110/416 | 2 | 双门/手动 | 蓝色 |

Parameters of weakly corrosive liquid safety cabinet:

Weak corrosion liquid safety cabinet: fire safety cabinet/explosion-proof cabinet, FM fire safety certified product in the United States

*Having passed the FM Approved Fire and Fire Protection Certification, the highest international industrial safety rating (the certificate can be found on the FM official website),

1. High quality steel plates with a thickness greater than or equal to 1.2mm are spot welded for longer service life and better explosion-proof performance;

2. There is a 38mm fire-resistant and heat-insulating air insulation layer between the two layers of steel plates, which is fire-resistant, heat-insulating, anti-theft, and explosion-proof;

3. The uniquely designed three-point linkage door lock allows for easy and flexible opening and closing of the 180 degree door panel. The patented embedded door lock enables dual person and dual lock management of hazardous chemicals;

4. There is a 5cm high leak proof liquid tank at the bottom of the cabinet to prevent accidental liquid leakage from overflowing;

5. Both sides of the cabinet are equipped with double ventilation holes with flame arresters and flame arresters (* flame arresters must comply with the latest FM6050 standard testing) to facilitate air dispersion and prevent the accumulation of harmful gases. Alternatively, they can be connected to the exhaust system through this connection;

6. The unique spill proof galvanized steel shelf can guide spilled materials to the back and bottom, flowing into the leak containment tank. The layers can be freely adjusted between the upper and lower layers every 6 centimeters, making it convenient to store chemical reagents of different heights and sizes. Each layer can bear a weight of more than 100kg* Install an integrated injection molded polypropylene tray with strong acid and alkali corrosion resistance on each layer of metal laminates to prevent dripping reagents from corroding the laminates;

7. The inside and outside of the cabinet are sprayed with epoxy resin paint, which has stronger corrosion resistance and is more suitable for use in harsh environments such as laboratories and workshops;

8. Strictly follow the OSHA regulations, and the cabinet body is equipped with static grounding conductive ports to facilitate the connection of static grounding wires and prevent the risk of sparks caused by static electricity accumulation;

*9. The cabinet is equipped with professional, standardized, and eye-catching patent warning signs. When illuminated by a flashlight, it can reflect light with high intensity and provide clear warnings even at night or in case of fire or power outage, making it easy to quickly identify during disaster relief;

客服1

客服1